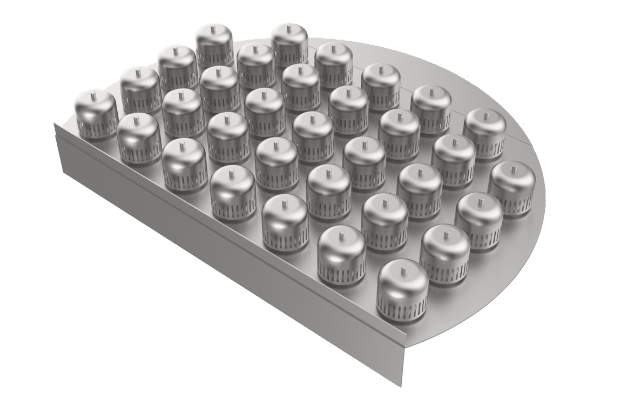

Tower Tray for Plate Column: Excellent Anti-Fouling Capacity

Tower tray is the main component of plate columns for promoting gas-liquid mass and heat transfer. It mainly consists of gas-liquid contact elements (such as float valves, bubble caps, sieve holes, etc.), liquid receiver, overflow weirs, downcomers (or downcomer plates), tray supports, and fasteners. It allows close contact between the two fluids for heat and mass exchange between the phases, separating liquid mixtures or gas mixture components. It is primarily used in high-pressure distillation operations, aiming to provide efficient separation and stable operation for plate columns.